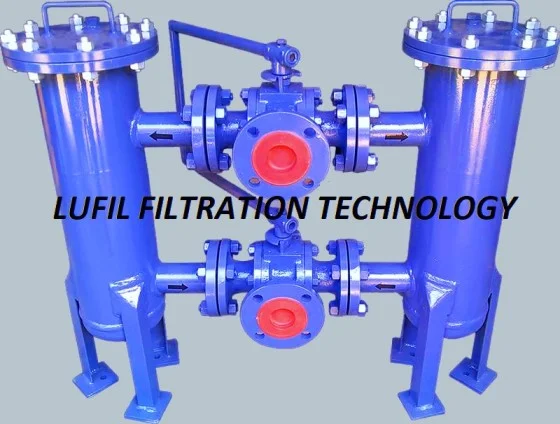

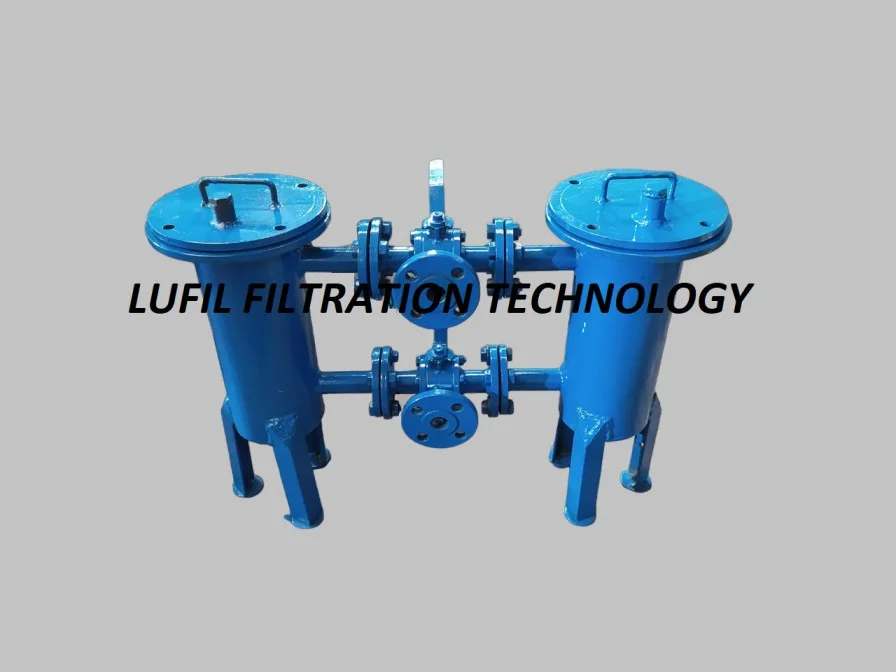

Duplex Fabricated Basket Strainer

Duplex lube Oil strainers are used in industries when you need to keep things clean for continued operation. We're proud to be recognized as a leading manufacturer of duplex bucket filters in India. We understand how crucial these filters are to make your equipment work well.

Working Principle

Duplex strainers consist of two baskets. Only one basket at a time is able to do the filtration process. When the working basket gets clogged due to dirt and needs cleaning, that time second bucket is used to continue the operation. Fluid from one to another basket gets transferred with the help of a valve placed between the two buckets which joints them. It can be either butterfly type or ball valve type depending upon the use and requirements.

Selection of Duplex Filters based on their material

Lufil offers cast iron, MS fabricated, and Stainless steel type duplex basket strainers. Duplex Filters made using cast iron material are used widely for cleaning light diesel oil (LDO), high speed diesel (HSD), and furnace oil (FO) in industries. Duplex Strainers which are made using MS material are widely used in raw water filtration and other types of industrial fluid cleaning. SS made duplex filters are used due to their non corrosive properties. They are widely used in food grade oil or drinking water cleaning.

Inner Element Specification

Lufil manufactures duplex systems known for their low maintenance and suitable for high pressure. The inner element made of SS304 & SS316 elements makes it corrosion resistant. Perforated inner elements are used to collect metal particles and dirt available in oil and water lines. We ensure reliable and efficient filtration solutions. Which can make your operations work better and save you money on maintenance.

Technical Specification

- Body Material

Mild Steel (MS) / Stainless Steel (SS) 304 / Stainless Steel (SS) 316 / Stainless Steel (SS) 304L / Stainless Steel (SS) 316L / Cast Iron (CI)

- End Connection

1" (DN 25), 2" (DN 50), 3" (DN 80), 4"(DN 100), 5"(DN 125), 6"(DN 150),8"(DN 200), 10"(DN 250), 12"(DN 300)

- Flange End Class

Flanged End to ANSI B 16.5, Class 150# / Class 300#

- Nominal Pressure Rating

PN 6 / PN 10 / PN 16 / PN 25

- Inner Element Micron Rating

20 to 1000 microns

- Operating Valve Type

Butterfly Valve / 3-Way Ball Valve

Applications

Chemical Process Industry

Power Generation

Marine and Shipbuilding

Textile Manufacturing

Mining Industry

Oil Refinery

Advantages

Uninterrupted Filtration

Low Maintenance

Versatility in Material

Pressure Rating Options

Micron Rating Flexibility