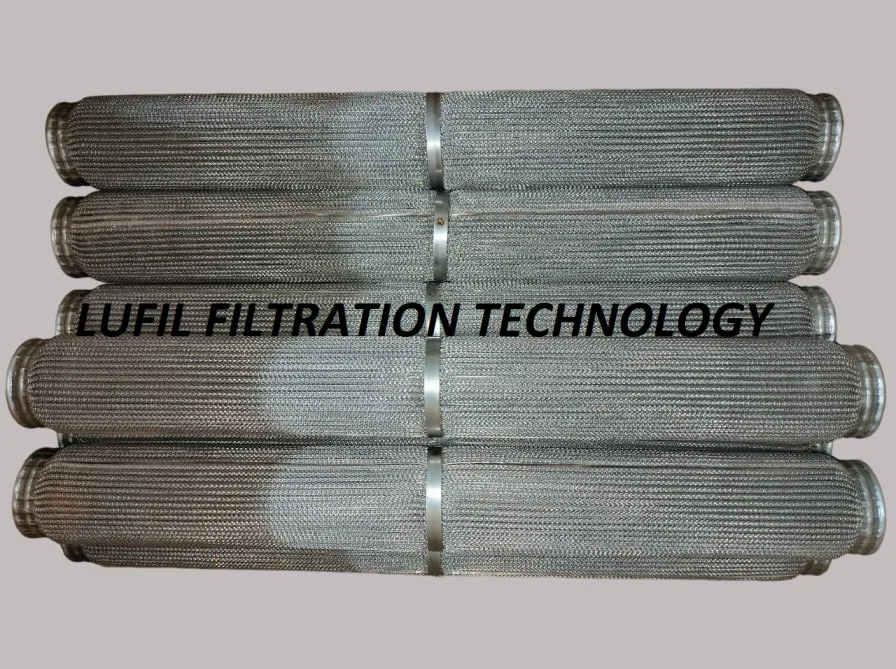

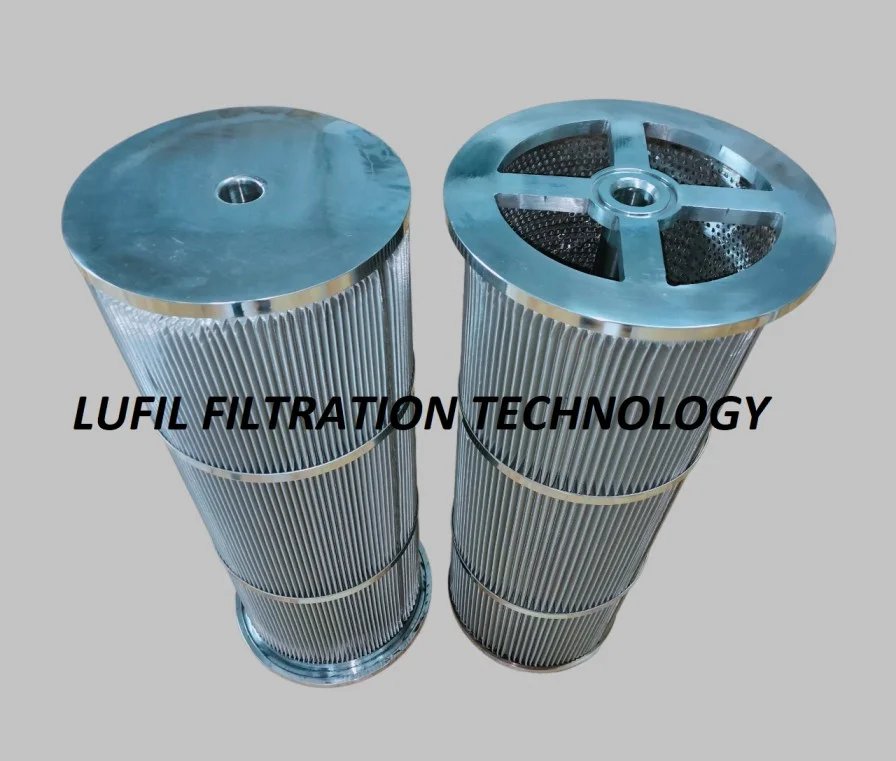

Welded Filter Element

Lufil Filtration Technology manufactures stainless steel welded filter cartridges in India. The welded design makes elements stronger and more efficient than glued cartridges, suitable for high-pressure and high-temperature situations.

They effectively remove dirt from liquids like water, chemicals, and pharmaceuticals, clean air and gas streams, and keep lubricating oils and hydraulic fluids clean.

Application

Welded filter cartridges serve different filtering needs depending on requirements. Polymer candle filters are used for super-efficient filtration, while sintered fiber candle filters use compacted fibers for precise filtering and can hold a lot of dirt. If you need maximum strength and cleanability, 100% welded filter cartridges are perfect choice. Turbine SS welded filter elements work well for high-flow situations and harsh environments, while SS 304 & 316 wire mesh welded filter elements give top-notch filtering and last a long time.

Advantages

Washable filter cartridges minimize waste production and cut operational costs. Reusable filter elements are a wallet-friendly and environmentally sound solution for long-term filtering needs. Lufil Stainless steel candles are suitable because they resist corrosion and stay strong, even in rough places. They are also used in industrial water filtration to remove impurities. Inline welded filters easily fit into existing filter systems, and wire mesh stainless steel welded cartridges are a strong and corrosion-resistant way to filter.

Technical Specification

- Material of Construction

SS 304 / SS 316 / SS 304L

- Design Type

Double open end (DOE) / Code 7 (222 O-ring) / Single open end / Rod type fitting

- Media Design Type

Wrap / Pleated

- Construction

100% Welded

- Welding Type

TIG welding / MIG Welding (GMAW) / Shielded Metal Arc Welding (SMAW)

- Micron Rating

1 to 500 microns

- Max Working Temperature

Up to 200 °C

- Max Working Pressure

Up to 330 Bar